Ọmarịcha mma nke ọma cvd mkpuchi siri ike na-egwe ọka Fanye Lathe Carbide Apmt1135pder 1120 Carbide Insert Factory N'ogbe

Nkọwa dị mkpirikpi

ungsten Carbide Cutting Fanye nwere ụdị dị iche iche na ihe dị iche iche maka ebumnuche ịkpụ dị iche iche yana nguzogide mmetụta dị elu nke bụ ezigbo nnọchi nke ntinye seramiiki, ntinye mkpuchi na ntinye alloy.Ọ na-adabara ọkụ usoro ihe mejupụtara ihe maka imeziwanye elu na ime ka ọ nwee ike inye mkpuchi zuru oke iji welie ihe mgbochi na-eyi, nkwụsị ọkụ, nkwụsị nke corrosion na mmetụta nke nchebe elu na mkpuchi pụrụ iche nke mkpuchi, mkpuchi na nnukwu-eduzi.

Ozi bụ isi

Carbide APMT PVD mkpuchi mkpuchi na-ejikarị maka indexable square ubu ọgwụgwụ egwe ọka cutters na ihu-egwe ọka cutters.Ihe ntinye APMT nwere IC emeziri nke ọma, mgbawa mgbawa kpụrụ akpụ dị mma.Ha nwere ihu mbelata dị nkọ na nke nwere ntụ na akụkụ enyemaka 11°.Ha nwere oghere ịghasa emepụtara dabere na ISO.A na-ele ya anya dị ka nke nwere akụkụ abụọ nke ịkpụ.Otú ọ dị, ha nwere n'ezie 4 ịkpụ n'ọnụ.mgbe etinyere ha na 90° indexable milling cutters na n'ọnụ abụọ na-aghọ dull, ha nwere ike tinye na 75° indexable milling cutters  na-aga n'ihu ndị ọzọ na-egwe ọka ngwa na ndị ọzọ abụọ n'ọnụ.APMT ga-abụ oké nhọrọ maka ọgwụgwụ ọrụ, ebe ọ bụ na ya. nwere ike melite arụpụtaghị ihe nke ukwuu.

Anyị carbide inerts nwere nnọọ elu kemịkalụ kwụsie ike, ịcha usoro, esemokwu nke ọnụ ọgụgụ dị nta, ala ọnwụ okpomọkụ, nwere ike igbochi usoro nke cuttib na inter-atomic mgbasa nke ihe, mgbochi osisi mma na iyi iguzogide bụkwa nnọọ elu karịa hard alloy.ma nwekwara mma red hardness na mgbochi crescent crater wear arụmọrụ.

Ụlọ ọrụ nke ngwa:

A na-eji ihe ntinye CNC na-atụgharị ma na-egwe ọka tungsten carbide ngwaọrụ n'ọtụtụ ebe: ụlọ ọrụ nrụpụta akpaaka, ụlọ ọrụ nrụpụta ebu, ụlọ ọrụ ụgbọ elu, ụlọ ọrụ nchekwa, ụlọ ọrụ nhazi dị arọ na ọtụtụ ubi ndị ọzọ.

anyị nwere ike ịmepụta ụdị dị iche iche tungsten carbide ịkpụ ngwaọrụ ntinye dị ka eserese ahaziri iche.

anyị nwere ike ịnye ngwọta nkwado n'ozuzu maka mpaghara machining.

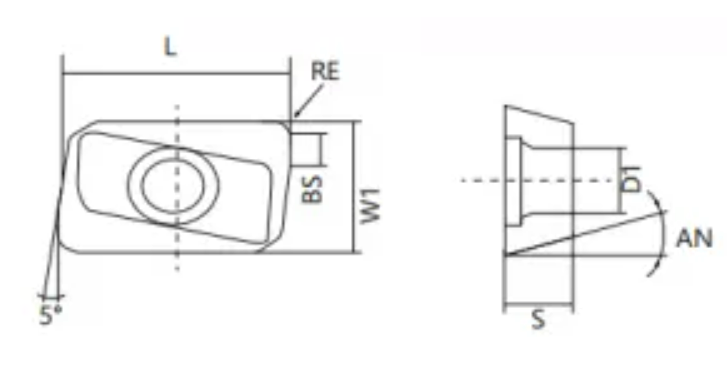

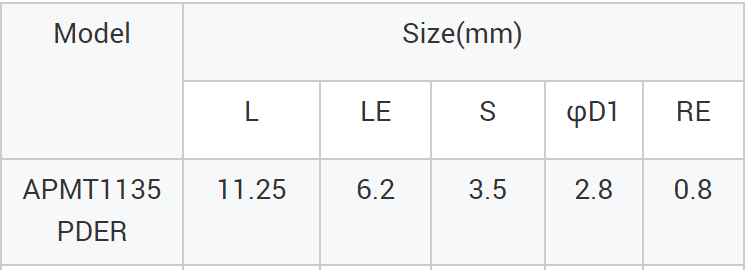

Nkọwapụta ngwaahịa

Ngwa QC

Ngwa mmepụta

Ngwa QC

Asambodo

Uru

1. A na-edozi nke ọma na-arụ ọrụ ike na-arụ ọrụ ọnụ na nsogbu ndị ọzọ.

2. Ịcha ọnụ mmasị designation dị mma ịchịkwa mgbawa eruba direction na-enweta magburu onwe elu àgwà.

3. Nka dị nkọ, obere ike ịkpụ.

4. Ezi machining elu àgwà.

5. Pụrụ iche mgbawa emebi imewe na-mbelata ọnụ nkọ na nchekwa.

6. Ezi mgbochi mmetụta mgbochi.

7. Magburu onwe ngwá ọrụ ndụ oge.

Atụmatụ

1.special n'elu ọgwụgwọ na mkpuchi.

2.suit maka nhazi nhazi dị elu.

3.fast nnyefe na top-edu ọrụ.

4. Ogo dị elu na ọnụahịa asọmpi.

5. A na-ejikarị eme ihe na ụlọ ọrụ nke ígwè ọrụ ígwè

6. Elu nkenke, ngbanwe dị mfe, ojiji n'ozuzu.