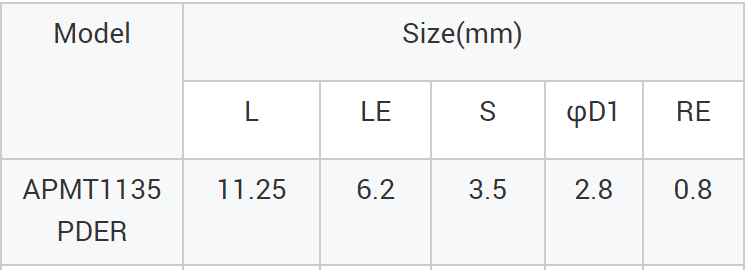

Atụmatụ igwe-egwe ọka APMT1135PDER CNC Ngwa ịkpụcha agụba Indexable Lathe Cutter Coated Milling Insert

Nkọwa ngwaahịa

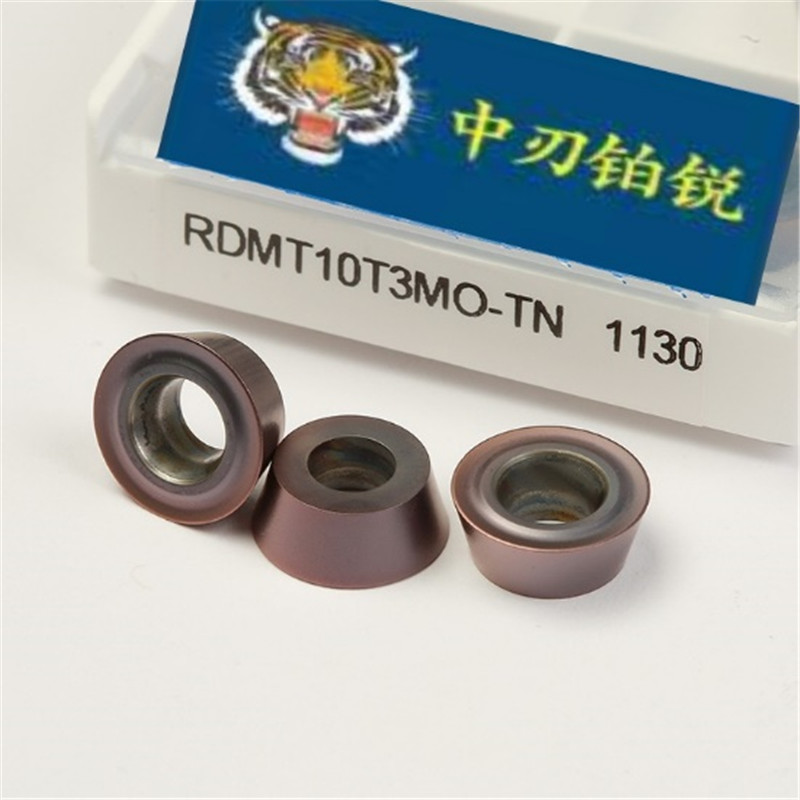

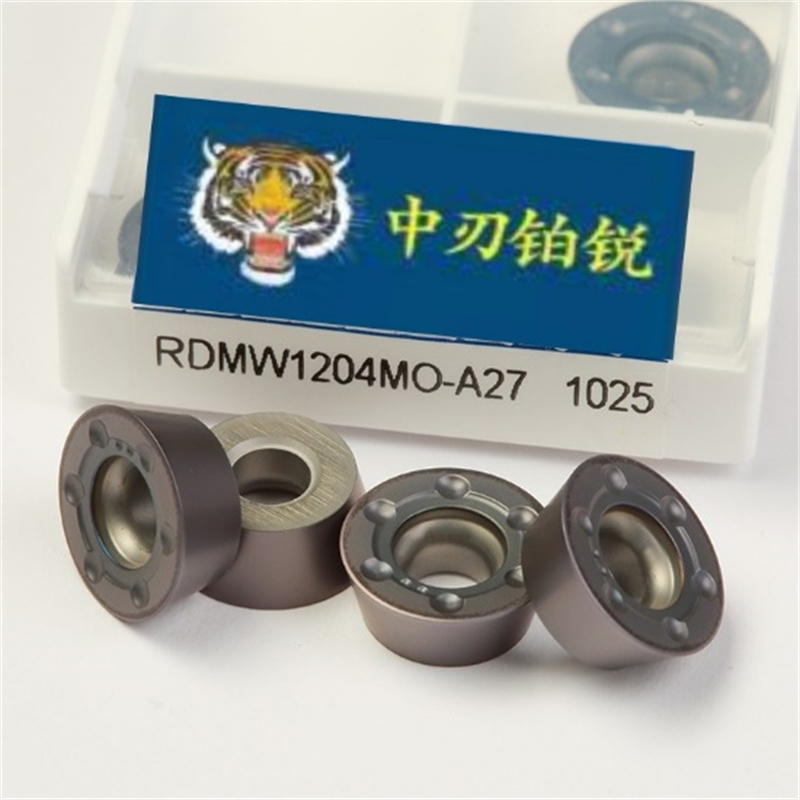

Carbide inserts ga-welded n'elu njide, na-eji na lathe maka machining nke dị iche iche ihe dị ka nkedo ígwè, ígwè, igwe anaghị agba nchara, nonferrous metal wdg A vasatail cutter nke a pụrụ iji maka ọtụtụ ụdị grooves, eri na chamfers. ;Nrụpụta akụrụngwa eccentric dị ka igbe igbe gearbox, yana mgbakọ dị elu, ọkachasị na ebe a na-arụ ọrụ na nkeji na-atụgharị na lathes.Tungsten Carbide Cutting Insert nwere ụdị dị iche iche na ihe dị iche iche maka ebumnuche ịkpụ dị iche iche yana nguzogide mmetụta dị elu nke bụ ezigbo nnọchi nke ntinye seramiiki, ntinye mkpuchi na ntinye alloy.Ọ na-adabara ọkụ usoro ihe mejupụtara ihe maka imeziwanye elu na ime ka ọ nwee ike inye mkpuchi zuru oke iji welie ihe mgbochi na-eyi, nkwụsị ọkụ, nkwụsị nke corrosion na mmetụta nke nchebe elu na mkpuchi pụrụ iche nke mkpuchi, mkpuchi na nnukwu-eduzi.

Carbide APMT PVD mkpuchi mkpuchi na-ejikarị maka indexable square ubu ọgwụgwụ egwe ọka cutters na ihu-egwe ọka cutters.Ihe ntinye APMT nwere IC emeziri nke ọma, mgbawa mgbawa kpụrụ akpụ dị mma.Ha nwere ihu mbelata dị nkọ na nke nwere ntụ na akụkụ enyemaka 11°.Ha nwere oghere ịghasa emepụtara dabere na ISO.A na-ele ya anya dị ka nke nwere akụkụ abụọ nke ịkpụ.Otú ọ dị, ha nwere n'ezie 4 ịkpụ n'ọnụ.mgbe etinyere ha na 90° indexable milling cutters na n'ọnụ abụọ na-aghọ dull, ha nwere ike tinye na 75° indexable milling cutters  na-aga n'ihu ndị ọzọ na-egwe ọka ngwa na ndị ọzọ abụọ n'ọnụ.APMT ga-abụ oké nhọrọ maka ọgwụgwụ ọrụ, ebe ọ bụ na ya. nwere ike melite arụpụtaghị ihe nke ukwuu.

Ngwa isi

Maka nhazi carbon ígwè, nkedo ígwè, igwe anaghị agba nchara

Ụlọ ọrụ nke ngwa

A na-eji ihe ntinye CNC na-atụgharị ma na-egwe ọka tungsten carbide ngwaọrụ n'ọtụtụ ebe: ụlọ ọrụ nrụpụta akpaaka, ụlọ ọrụ nrụpụta ebu, ụlọ ọrụ ụgbọ elu, ụlọ ọrụ nchekwa, ụlọ ọrụ nhazi dị arọ na ọtụtụ ubi ndị ọzọ.

anyị nwere ike ịmepụta ụdị dị iche iche tungsten carbide ịkpụ ngwaọrụ ntinye dị ka eserese ahaziri iche.

anyị nwere ike ịnye ngwọta nkwado n'ozuzu maka mpaghara machining.

Nkọwapụta ngwaahịa

Ngwa mmepụta

Ngwa QC

Asambodo

Uru

1. A na-edozi nke ọma na-arụ ọrụ ike na-arụ ọrụ ọnụ na nsogbu ndị ọzọ.

2. Ngwunye nke ọma, obere ike ịkpụ.

3. Ezi machining elu àgwà.

4. Magburu onwe ngwá ọrụ ndụ oge.

5. A na-anabata obere iwu maka nnyefe ngwa ngwa na iji nyere gị aka belata ọnụ ahịa ngwaahịa.

Atụmatụ

1. Magburu onwe na-eyi nguzogide, ezigbo ike na-ekpo ọkụ, melite mmepụta mmepụta.

2. Ala nkenke ma na-egbu maramara, mmetụta ịkpụchasị mma

3. PVD mkpuchi hụ na ogologo ndụ ngwá ọrụ.

4. Nwere ike dakọtara ọtụtụ n'ime ika ngwá ọrụ mmanya / njide.