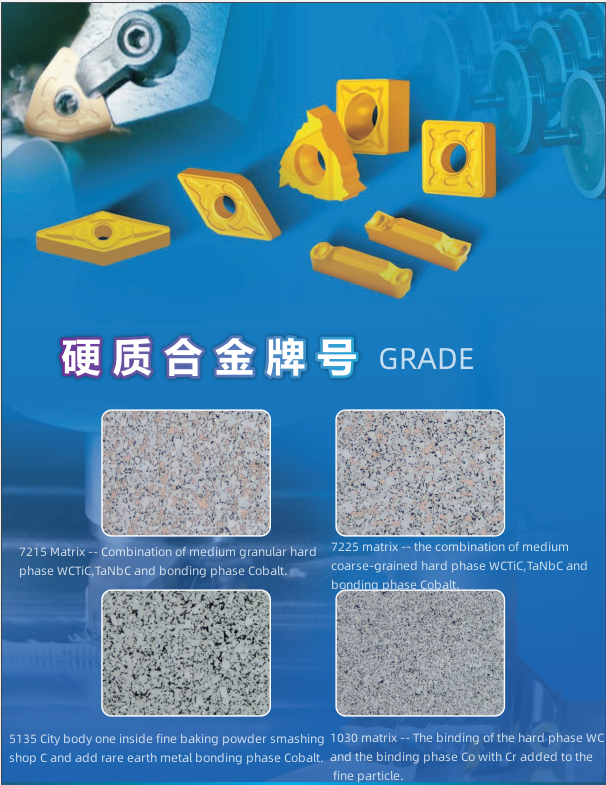

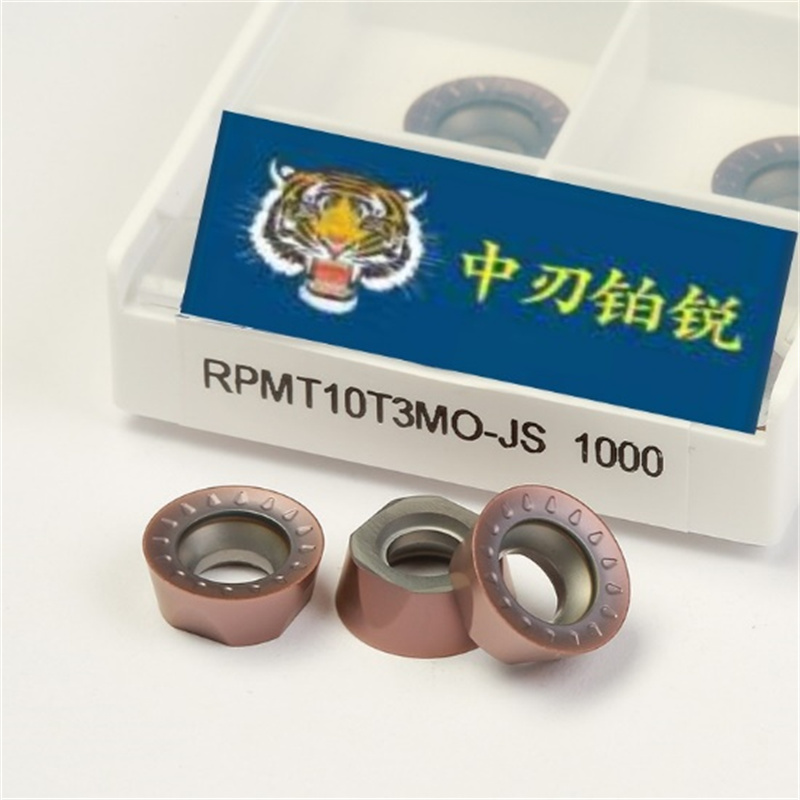

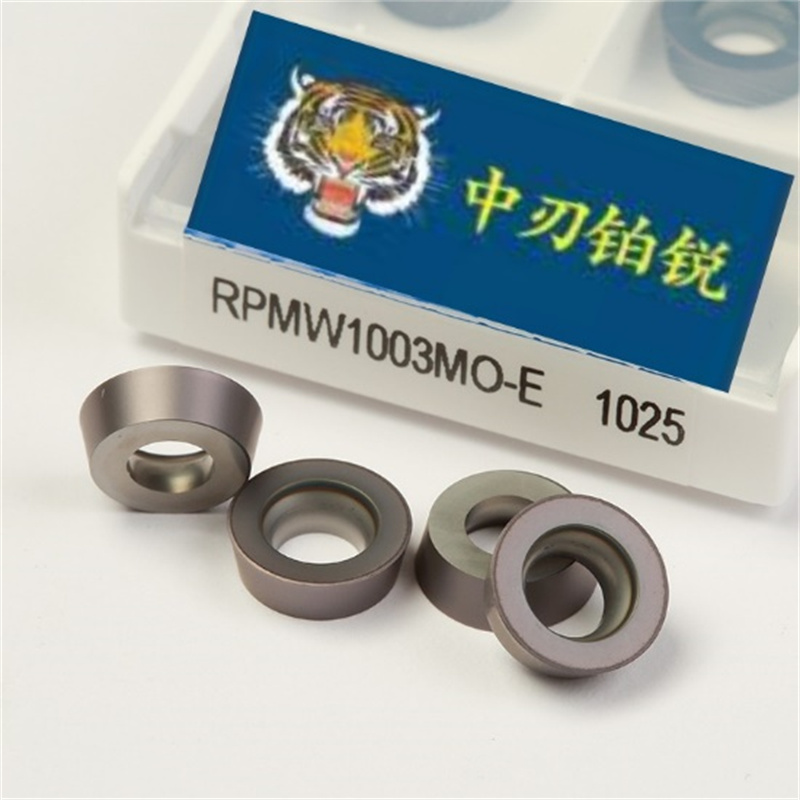

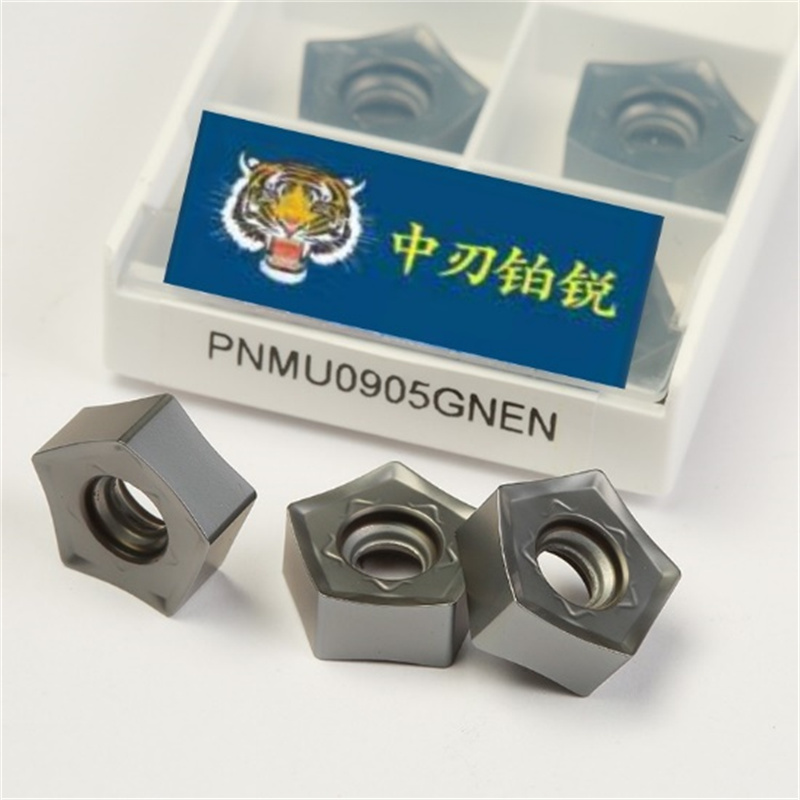

RPMT RDMW1204MO Indexable Milling Fanye Carbide Na-etinye Ngwa Lathe Ihu Igwe Ngwunye ihu

Okwu mmalite ọkwa ihe

Okwu mmeghe nke ntụgharị ihe:

7215 nwere ike dị elu na ike nke nnukwu matrix na-eguzogide toxicity, jikọtara

na MT-TICN, AL2O3, TIN magburu onwe Nchikota mkpuchi usoro, na mgbe ahụ

site elu mkpuchi post-ọgwụgwọ ikpochapụ esịtidem nchegbu nke agụba oyi akwa, adabara nkịtị ígwè finishing.

7125 onu nchekwa nke elu ike, elu siri ike matrix jikọtara na MT-TICN na superfriction AL203 mkpuchi usoro, na mgbe ahụ site elu mkpuchi post-ọgwụgwọ usoro ikpochapụ esịtidem nchegbu nke mkpuchi, adabara nkịtị ígwè siri ike nhazi, ọkara-emecha na akụkụ nke workpiece roughness chọrọ na-adịghị elu finishing.

4025 elu corrosion eguzogide, na site a ụfọdụ nsogbu sintering usoro nke elu ike matrix na MT-TICN na ibu oké AL2O3 mkpuchi magburu onwe Nchikota, na elu mkpuchi post-ọgwụgwọ technology nweta ezigbo mkpuchi elu, adabara na ike ike machining, ọkara-emecha. na imecha nkedo ígwè.

1030 ezi ọka, magburu onwe deformation eguzogide na site na nrụgide sintering usoro iji nweta ultra-elu ike na-eyi iguzogide matrix, na nano PVD mkpuchi usoro, na mgbe ahụ site elu mkpuchi post-ọgwụgwọ nweta ezigbo mkpuchi elu, adabara nkịtị ígwè finishing, ígwè emenyụ, chromium plated ígwè na igwe anaghị agba nchara ọkara-emecha na finishing.

1120 ultra-fine ọka, magburu onwe deformation eguzogide, na site na nrụgide sintering usoro iji nweta ike dị elu na-eyi na-eguzogide matrix, na nano SI nwere PVD mkpuchi usoro, mgbe elu mkpuchi post-ọgwụgwọ nweta ezigbo mkpuchi elu.Kwesịrị ekwesị maka ịkwanye na ịcha ígwè nkịtị, ígwè siri ike na nkedo ígwè.

Mmalite nke igwe igwe na ihe ngwuputa

1030 NC-TIALN mkpuchi jikọtara ya na ike na ductile matrix nke ezi ahụ bụ adabara keadighi rarii na ọkara mechara egwe ọka nke ụdị nile nke esichara ihe.Ịgba, ịcha na mkpọpu nke ọkara oghere.

1130 NC-TIALN mkpuchi nwere SI jikọtara ya na ezigbo ahụ na ịdị mma siri ike nke matrix alloy siri ike, dabara adaba maka igwe anaghị agba nchara, oge nkedo na ọkara imecha na nhazi, iji nweta nchikota zuru oke nke nchekwa na iyi nguzogide.

5035 agbakwunyere akwa na ihe ndị na-eguzogide okpomọkụ dị elu nke mkpuchi CVD, mkpuchi mkpuchi dị elu na nguzogide okpomọkụ dị elu iji nye nchebe dị irè maka mbepụ ọnụ, teknụzụ ọgwụgwọ mkpuchi pụrụ iche, mkpuchi na matriks siri ike, dabara adaba maka alloy okpomọkụ dị elu, titanium alloy ihe nkenke. nhazi igwe ihe.

5135 NC-TIALN mkpuchi nwere SI jikọtara ya na carbide matrix nwere mmetụta siri ike dị oke mma, dabara adaba maka akụkụ nchara, igwe anaghị agba nchara, ịcha mmiri, ịcha mkpụrụ miri emi, nhazi nri ngwa ngwa na nhazi oghere oghere.

Ngwa

Ngwa isi:Maka nhazi carbon ígwè, nkedo ígwè, igwe anaghị agba nchara

Iji dị iche iche hardness nke ebu workpieces, anyị nwere ike nwalee ndụ nke ịcha ngwaọrụ n'ụzọ ziri ezi.Ọkachamara na igwe igwe igwe ma ọ bụ igwe igwe anaghị agba nchara ma ọ bụ igwe nkedo igwe ma ọ bụ aluminom alloy, ihe ntinye igwe anyị bụ nke pụrụ iche sitere na ala ultra-fine carbide, yana teknụzụ mkpuchi AlTiN dị elu.Ndị a na-eme ka onye na-egwe ọka anyị nwee mmetụta nhazi dị mma yana àgwà kwụsiri ike ruo elu.

Nkọwapụta ngwaahịa

| Ụdị | Akụkụ (mm) | ||

| D | S | D1 | |

| RDMW120400-PR | 12.00 | 4.76 | 4.40 |

| RDMW1204MOT-PM | 12.00 | 4.76 | 4.40 |

| RDMW1204MO-TT | 12.00 | 4.76 | 4.40 |

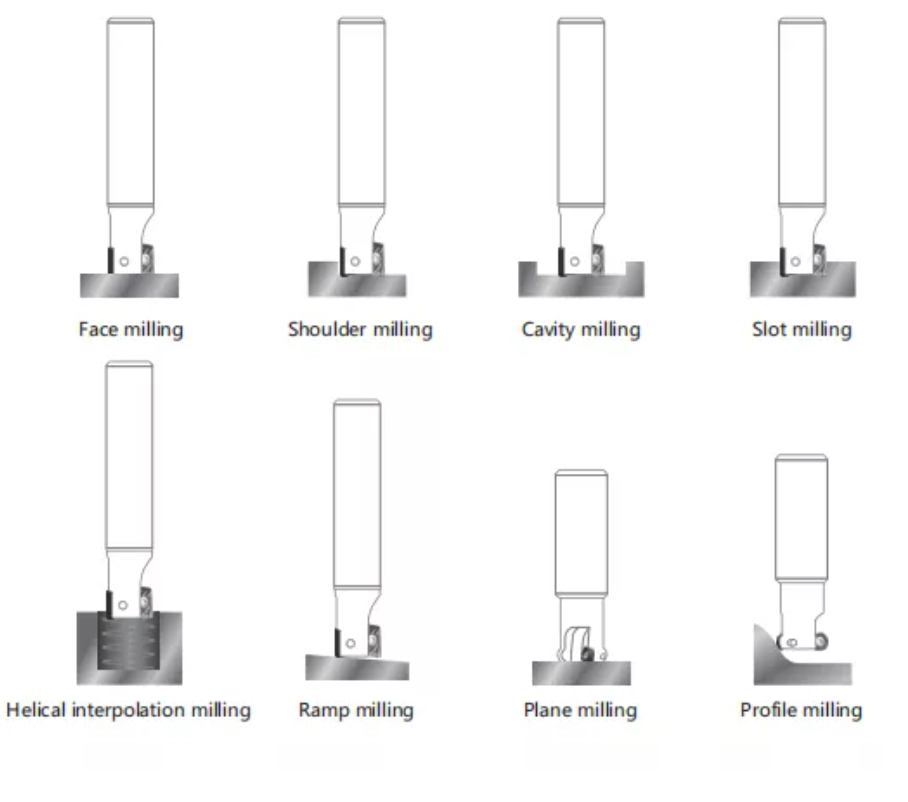

Ma ị chọrọ a n'ozuzu-egwe ọka ma ọ bụ arọ egwe ọka inserts maka ihu-egwe ọka, ubu-egwe ọka, oghere-egwe ọka, profaịlụ egwe ọka, ma ọ bụ ramp-egwe ọka, ma ọ bụ ọbụna-egwe ọka elu chọrọ nke elu ire ụtọ, Anyị engineer nwere ike gbanwee gị imewe n'ime a-egwe ọka ntinye na dị nnọọ ụbọchị.

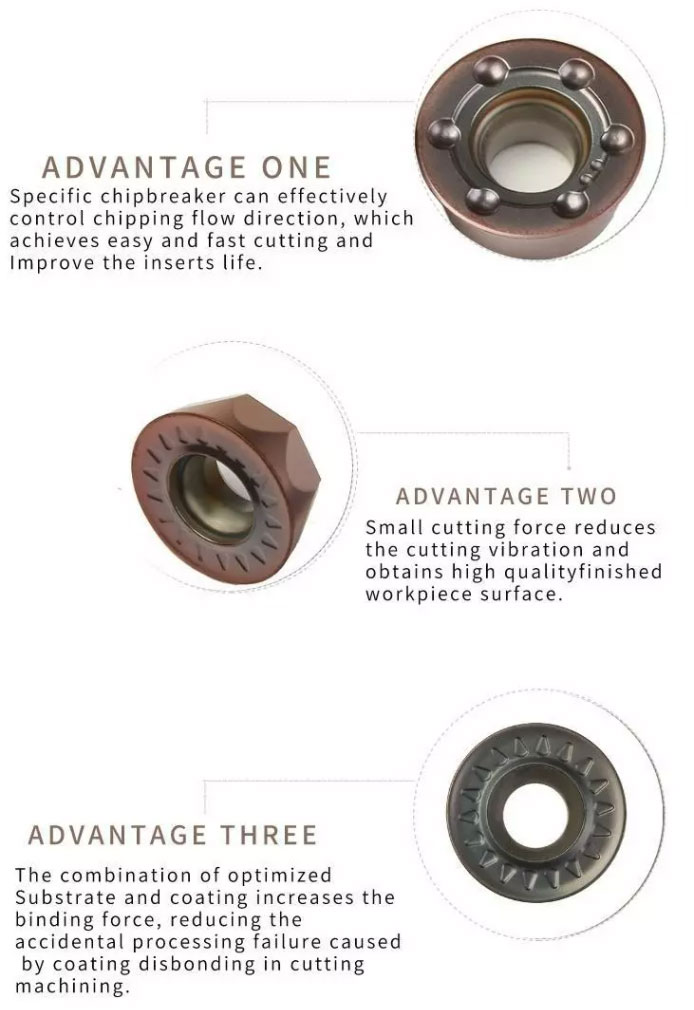

Ngosipụta mkpuchi

Asambodo

Ngwa mmepụta

Ngwa QC

Ọrụ anyị

Ọrụ tupu ire ere:

Anyị nwere ndị ọrụ ahịa ndị ọkachamara, ndị nwere ike ịmata nkọwa gbasara mkpa gị ma nye nzaghachi.

Ọrụ ire ere:

Mgbe mbinye aka nke nkwekọrịta ahụ, ndị ọrụ ahịa ndị ọkachamara anyị ga-ekwurịta okwu ma rụọ ọrụ na usoro mmepụta ihe ma ọ bụ mgbanwe gị.

Ọrụ mgbe ire ere:

Anyị ga-ahazi nlọghachi na mgbanwe nke ngwaahịa n'oge ma ọ bụrụ na ha nwere nsogbu dị mma.N'otu oge ahụ, a ga-eme nletaghachi mgbe niile iji mara ọnọdụ ọrụ nke ngwaahịa anyị.